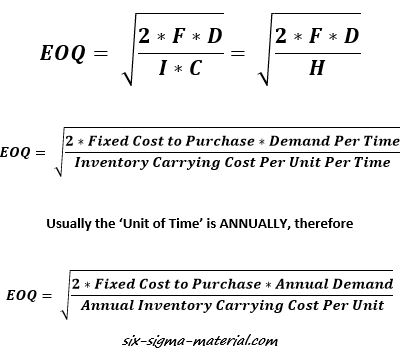

EOQ 2xDxO H ie. EOQ square root of.

Eoq Wilson Formula Calculation Free Excel Examples

Calculation of EOQ.

. EOQ Economic Order Quantity or ELS for single-step manufacturing. Economic Order Quantity is Calculated as. D Annual demand in units of a product.

Simply following the formula without revision could lead to excess inventory building up in your warehouse. While this is the case for most products the formula might not work for every product for this reason. For a company X annual ordering costs are 10000 and annual quantity demanded is 2000 and holding cost is 5000.

The well-known Economic Order Quantity EOQ model assumes that the demand and ordering cost is constant over time and there is no lead-time for each order delivered. The EOQ formula is most useful for constant or smooth demand pattern. Economic Order Quantity 2SDH EOQ 21000020005000.

Q 2 D S H where. The economic order quantity formula is one approach to striking this balance. EOQ- Square root of 2xDxS H.

Economic Order Quantity Formula Example 1. As a result the EOQ is calculated as follows. This is the amount of product that you sell in a given year.

2 x 2 x 2000 units 7 338 units with rounding Therefore to reduce inventory costs and satisfy demand this business should always place an order for 33 or 34 shirts. If your demand drops between placing one order and the next you may find you dont need to order the same quantity as your original EOQ formula recommended. O Ordering cost per order.

The below table shows the calculation of the combined ordering and holding cost at. Since the average demand is 100month this quantity satisfies demand for an average of 164 months which is then rounded to 2 months. Another advantage pertaining to the EOQ model is that it is able to provide specific numbers particular to the business regarding how much inventory needs to be held when to re-order it and how many items are needed to be ordered.

The EOQ formula is as follows. In purchasing raw material or other items of inventory it tells the amount to order and the best timing of our orders. EOQ Square root of 2 x demand x ordering cost carrying cost Demand.

The EOQ formula contains the ordering. Let us suppose that MrX deals in bicycles and has an annual sale of 6000 units. D Demand per Unit of Time assumed constant rate of demand.

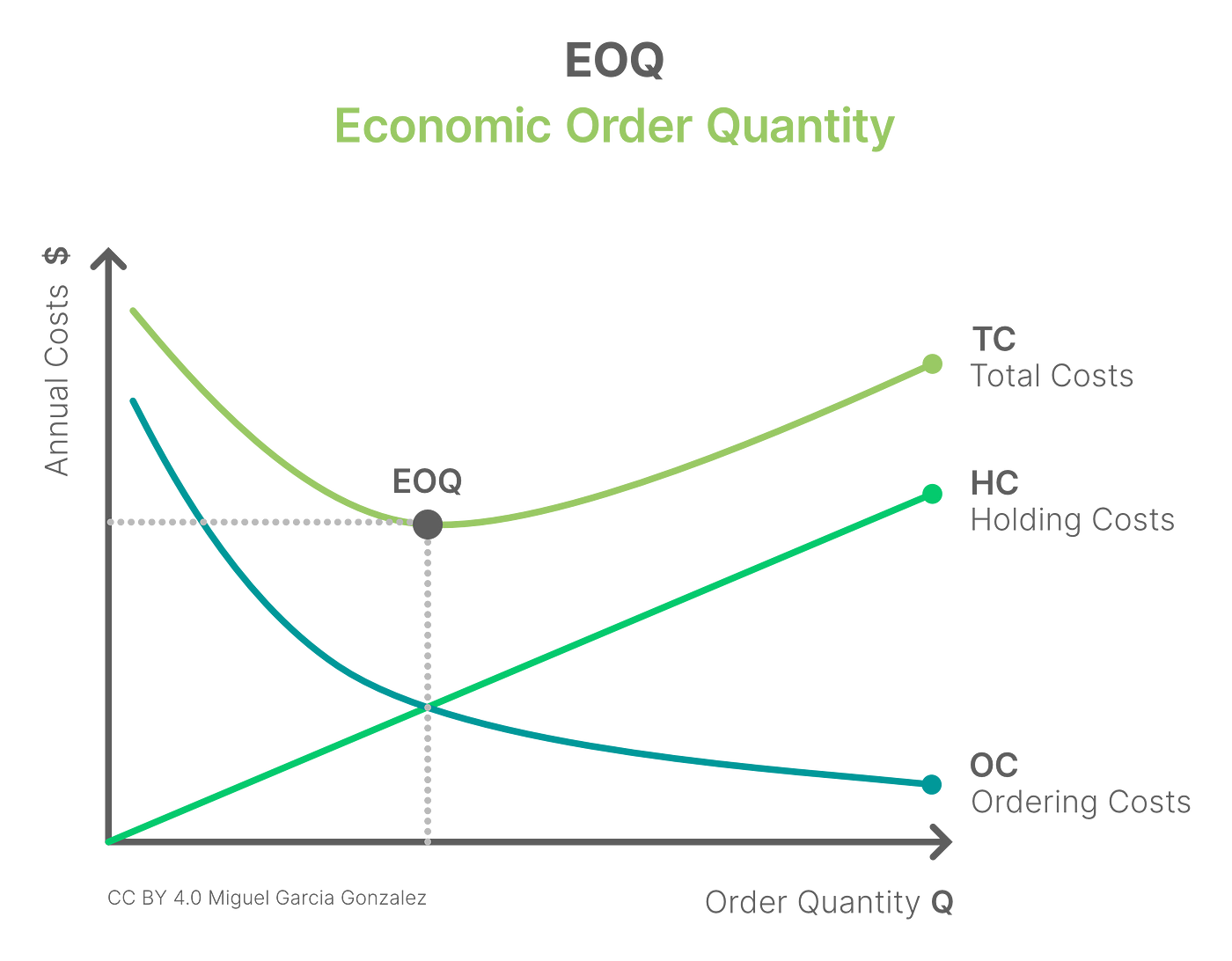

For finished goods inventory it enables us to exercise better control over the timing and size of production runs. While this inventory management model was first developed in 1913 by Ford W. Economic Order Quantity EOQ EOQ is a mathematical formula designed to minimize the combination of annual holding costs and ordering costs.

You could also calculate your EOQ rate with. The calculation for annual holding cost can be done by dividing the order quantity by two and multiplying it by the holding cost per unit of the product. Combine ordering and holding cost at economic order quantity.

You can then plug these numbers into the Wilson Formula otherwise known as the EOQ formula. The EOQ formula uses an annual demand rate in most cases. The demand rate is the amount of inventory that a company sells annually.

2setup costsdemand rate holding costs. Ch cost of holding per unit of inventory. Divide the EOQ just computed by the average demand to obtain the average number of periods per order and round to the nearest integer but greater than zero Example.

The demand is how much inventory is used per year or how many units are sold per year. O highly seasonal constant or smooth sawtooth lumpy or sporadic. Economic order quantity EOQ For businesses that do not use just in time JIT inventory management systems there is an optimum order quantity for inventory items known as the EOQ.

So to minimize the total cost differentiate Total Cost TC wrt. The ideal order size to minimize costs and. The formula for EOQ is given by.

Also referred to as optimum lot size the economic order quantity or EOQ is a calculation designed to find the optimal order quantity for businesses to minimize logistics costs warehousing space stockouts and overstock costs. Q and equate to zero. Harris 1913 The purpose of the EOQ model is to help the manufacturer determine the best order size that could minimize the total inventory holding cost and ordering cost.

Here D Annual demand in units of a product. The formula for calculation of the EOQ is. S Ordering cost per order.

The EOQ formula taken up in this unit is a very useful tool for inventory control. Economic Order Quantity Formula Example 2. H Holding cost per unit of the product.

To calculate EOQ you need. Square root of 2xDxO H. You can also use our EOQ Calculator.

The EOQ model fails to consider current stock levels in your warehouse network. H Holding cost per unit of the product. Answer is option c constant or smooth.

Total Inventory Carrying Cost. So the calculation of EOQ Economic Order Quantity Formula for holding cost is 2002 1. Co cost per order.

41 if total quantity is OB ie Q then average inventoryQ2 Putting expressions of 2 ad 3 in 1 The objective is to determine the quantity to order which minimizes the total annual inventory cost. EOQ formula and EOQ factors. Q EOQ units D Demand in units typically on an annual basis S Order cost per purchase order H Holding costs per unit per year beginaligned Q sqrt frac2DS.

The basic a View the full answer. Therefore holding cost 100. S Setup cost per purchase order.

The aim of the EOQ model is to minimise the total cost of holding and ordering inventory. Question 5 1 point The EOQ formula is most useful with which of the following. The EOQ formula assumes that you have consistent yearly demand.

Harris the calculations for this production-scheduling tool have since been refined. The EOQ formula is the square root of 2 x 1000 shirts x 2 order cost 5 holding cost or 283 with rounding. D demand per year.

There is a lot of hype about just in time inventory systems JIT which achieve smaller inventories through very frequent orders but frequent ordering can often result in an over-spending on ordering costs. The demand of the item per year the cost per order and the cost of holding per unit of inventory. The EOQ computed earlier is 164.

F Costs to execute an Order or Acquisition Costs Fixed Costs per EOQ Batch I Inventory Carrying Rate expressed as C Cost per Unit unit H Holding Carrying Costs per Unit per Unit of Time I C. Business Specific Maintaining sufficient inventory levels to match customer demand is a balancing act for many small businesses. The demand remains constant according to the assumptions made by EOQ.

Question 5 1 point The EOQ formula is most useful with which of the following demand patterns.

Calculate The Economic Order Quantity Eoq

Revisited Economic Order Quantity Eoq By Miguel Garcia Gonzalez Supply Chain Unpacked Medium

What Eoq Model Types Can Be Used Brightwork Research Analysis

0 Comments